|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Three centuries’ heritage of wine history handed down from father to son has taught us that the “Nectar of Bacchus” is a natural product; a direct child of a natural transformation that requires no external intervention or manipulation. Our role as wine-makers is merely that of following the wine in its precise course of transformation and refinement without forcing it - where each single operation respects nature’s time-frame.

The same philosophy that we observe in the vineyard guides us during the wine-making process, when we pay particular attention to enhancing to the maximum point the special aromas jealously guarded in our grapes.

|

|

|

|

|

|

|

In September and October, when the grapes are ripe and the harvesting moment is optimized through an evaluation of the maturation curve, grape-picking begins. This operation is conducted rigorously by hand, so as not to ruin the fruit.

|

|

|

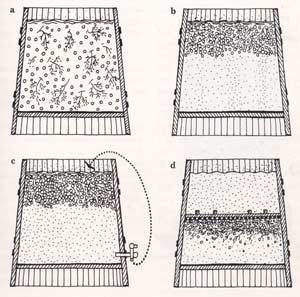

Having reached the wine cellar, the precious grapes are removed from their stalk and soft pressed. The grape press is pumped delicately in fermentation vats, where a “cold maceration” begins, a period of contact of must and skins without fermentation that permits the extraction of all those natural substances which will ennoble our wines.

|

|

|

|

|

|

|

The process includes various manual “follature” (plunging the cap). We then proceed to the alcoholic fermentation, which usually lasts for a week, followed in its turn by a final maceration period. |

|

|

All these transformations take place in stainless steel vats equipped with temperature-control systems.

|

|

|

|

|

After these four weeks, the wine is removed from vats to be separated from the skins. It then returns to the clean vats for the malolactic fermentation, a transformation in which the malic acid evolves into lactic acid, giving the wine greater depth and softness, and enriching that refinement we love so much.

|

|

|

Once the two fermentation processes are completed, the wine is transferred into oak casks, where refinement “of the yeasts” begins through frequent mixing (batonnage), and the precious yeasts are kept in constant suspension so that the wine mass benefits. This ancient system favours the aromatic enhancement of the wine, which highlights the very special character that a great wine must increasingly express in future years.

|

|

|

|

|

This type of ageing inevitably implies a certain absorption of the wine into the wood, which together with natural evaporation, leads inevitably to a reduction of the amount in the barrel. for For this reason, elements (extra quantities of the same kind of wine) called “colmature” (or fillers) are routinely introduced (twice a week); to optimise this practice, glass “fermentation bungs” are utilised, which in addition to keeping the barrel level under control, allow for a gaseous exchange between the wine and the atmosphere.

|

|

|

History teaches us that there are no technologies which can substitute time in the maturation of a great wine. It is up to the skill and proven experience of the master wine-makers who attend to each wine as it ages, using specific methods and time-frames, avoiding an indiscriminate use of wood, which would only take away the special aromas and nature of each product.

|

|

|

After frequent tasting of the different casks, and a careful and rigid selection process, the wine is poured into vats for the final “blend”, where the fusion of each single characteristic will contribute to creating the perfect combination for an elegant, aromatic symphony.

The bottling date will then be determined after long and careful taste evaluations.

|

|

|

|

|

|

|

|

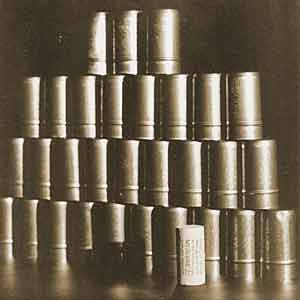

Cork is then carefully selected and checked immediately before being used in the bottling facility.

|

|

|

After capsulation, the wine is put to rest in large crates of 500 bottles each, and stored in warehouses for further refinement.

|

|

|

|

|

Labelling and packing in crates is done immediately before shipping, thus guaranteeing a unique and impeccable presentation.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|